| |

DRYER |

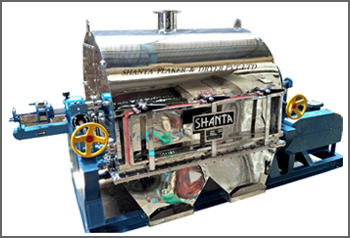

SINGLE DRUM DRYER |

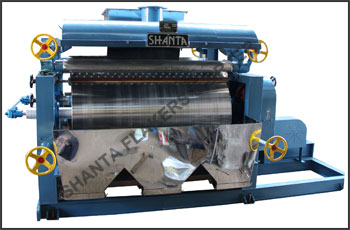

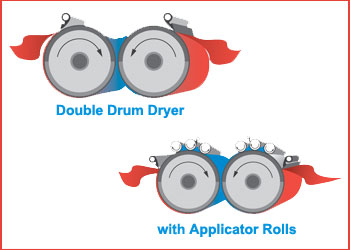

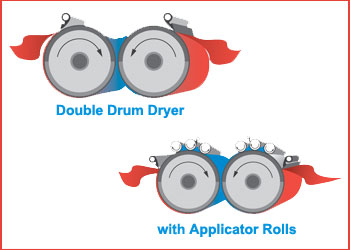

DOUBLE DRUM DRYER |

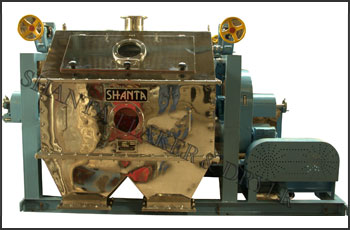

A version designed for specific applications and chemicals. In this machine, the roll sitsunderneath and dips into the product, picking up a liquid layer for transfer to the drum – similar to a printing press. A version designed for specific applications and chemicals. In this machine, the roll sitsunderneath and dips into the product, picking up a liquid layer for transfer to the drum – similar to a printing press.

The applicator rolls make it easy to regulate

product feed. In addition, they have a

kneading effect, preventing lump formation

in stickier materials. With perfect distribution

along the length of the drum, the system

is ideal for processing pasty or pulpy

products. |

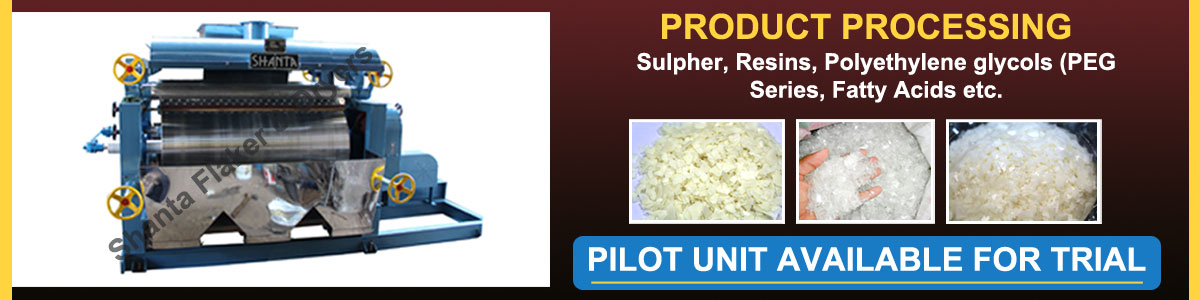

With this system, product is fed into the

nip between a pair of drums (which always

rotate in opposite directions). This small

gap between the drums is finely adjustable

to optimize the film thickness. With this system, product is fed into the

nip between a pair of drums (which always

rotate in opposite directions). This small

gap between the drums is finely adjustable

to optimize the film thickness.

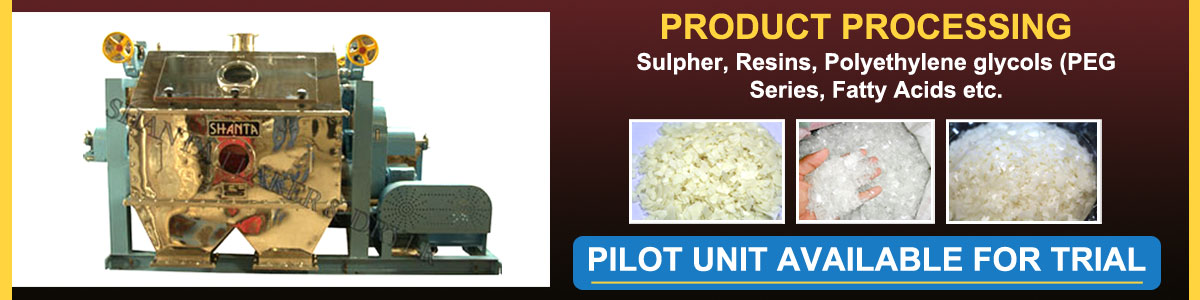

The double drum dryer with applicator rolls

is suitable for customers with more variables

in their product range. This multifunctional

setup offers the greatest versatility

– combining the advantages of both

the single and double drum dryer systems |

|

|

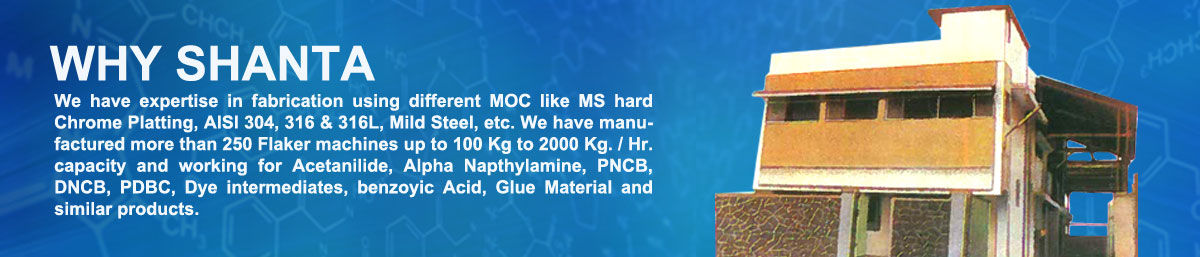

Shanta Who have proven the records of two decades experience in Chemical Flaker manufacturing and are known for Quality. Competitive Price and Delivery in Time.

We have installed 300 FLAKER MACHINES all over INDIA in varios products and various types. Special fumetight FLAKER Design for Hazards Gases, Flammable Materials and for to prevent the dusty atmosphere with customs build with full range.

PRINCIPALS OF OPERATIONS

The SHANTA Flaker & Drum Dryer Co. Pvt. Ltd. Offer a Flaker to convert molten Chemical into solid flakes.This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from inside surface of the drum. An adjustable scrapper continuously removes the solidified from the drum surface in flake forms. |

| |

|

DRUM : MATERIAL OF CONSTRUCTION |

| It can be Mild Steel, Stainless Steel with / without Hard Chrome plating, Normally monoblock for weldable material . This construction ensure lifelong alignment. Surface will be machined and ground finished. Drum roating on antrifriction self aligning ball/roller bearing with standard housing. |

| |

DRIVE |

| Heavy duty drive is designed for smooth, continuous and troble free running. V-pulley or variable speed arrangement also provided for optimum performance. |

| |

COOLING / HEATING |

| Water through spray pipe with reading glands / steam rotary. |

| |

STANDARD SIZES : DRUM DIMESIONS |

| DIMESIONS : (mm) |

600 |

1000 |

1000 |

1250 |

1250 |

1250 |

1500 |

| LENGTH : (mm) |

1000 |

1250 |

2000 |

2000 |

2500 |

3000 |

3000 |

| GROSS AREA : (mm) |

2.00 |

4.00 |

6.00 |

8.00 |

10.00 |

12.00 |

14.50 |

|

| |

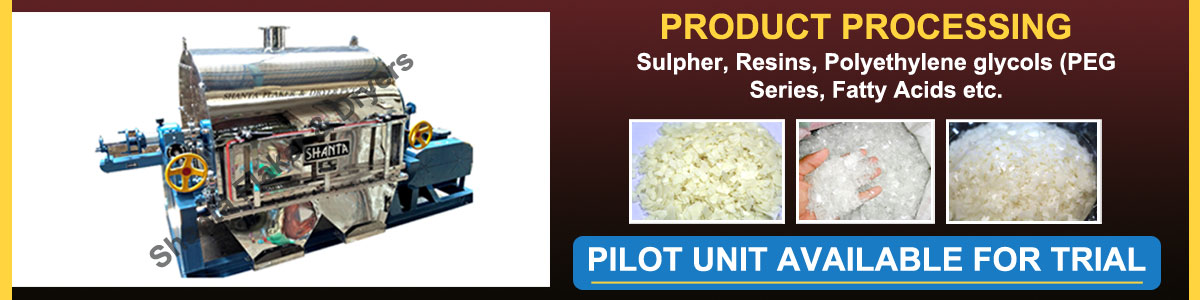

STANDARD ACCESSORIES |

| The FLAKER MACHINE will be complete with 1440 R.P.M. 3 phase, 415 Volts, TEFC / ISD motor, with Gear Box, Tray, Hopper M.S. Hood, Belt Guard, Machine mounted on heavy base plate for trouble free service. |

| |

OPTIONAL FEATURES |

| Screw Conveyor, Flake Breaker, Film Thickness controller, Complete enclosure of Hazards applications. |

| |

PILOT PLANT |

| We have a pilot unit which availble for to take running trial on receipt of a sample about 15kg. We carry out the test on it to produce reliable in formations on output and for the scalling of purpose. |

| |

A version designed for specific applications and chemicals. In this machine, the roll sitsunderneath and dips into the product, picking up a liquid layer for transfer to the drum – similar to a printing press.

A version designed for specific applications and chemicals. In this machine, the roll sitsunderneath and dips into the product, picking up a liquid layer for transfer to the drum – similar to a printing press. With this system, product is fed into the

nip between a pair of drums (which always

rotate in opposite directions). This small

gap between the drums is finely adjustable

to optimize the film thickness.

With this system, product is fed into the

nip between a pair of drums (which always

rotate in opposite directions). This small

gap between the drums is finely adjustable

to optimize the film thickness.